DXF Preferred File Format

DXF is the file format of choice.

Creating your Drawing

Start with a fresh drawing, otherwise you can end up with faulty drawings. Common issues with old drawing can be

- Leftover lines/ double lines.

- Lines not Joined/ Overextended Lines

- Views, Blocks & Layer from old drawings, not related to you profile part

Holes

The rule is that a hole should NOT be smaller than the thickness of the material you are cutting.

Example: 5mm material = 5mm or greater diameter hole, 8mm material = 8mm or greater diameter hole.

Leave Room Between Cuts/ Holes

When making slots, cuts or holes to avoid quality issues it is recommend that the minimum distance between cuts is equal or greater than the thickness of the material being cut. If cutting 5mm material, 5mm or more between holes/ slots etc… The rule is to leave a bridge as wide as the thickness of the material.

One Part per Drawing

Delete anything that isn’t necessary. No side-views, dimensions, borders, just a flat pattern of what you want profiled.

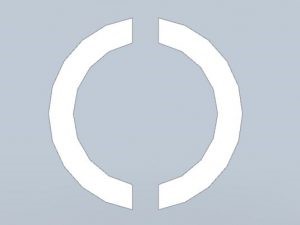

Connect the Letter Insides

Letter “O” with connecting bridges

This is very often overlooked. When you want to add some words on your sheet of metal, consider the fact that the insides cannot levitate in the air. In our example, the inside ring of “O” is connected by 2 bridges. Otherwise, the inside ring would fall away.

Check the Scale

All drawings must be 1:1. Check the scale after creating the DXF files. Our system gives your sheet’s general dimensions after uploading the drawings. Make sure it corresponds to reality. If not, adjust the scale.

Overwriting Dimensions

We receive engineering drawings that have overwritten dimensions on them. If you just delete the old value and replace it with the right one, the scale will still stay the same. The dimension does not drive the line length.

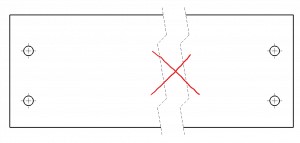

Breaking the Views

Breaking a view may be a useful tool to make a drawing easily readable for a person. However, engineering drawings heading to automated cutting are read by computers. Breaking a detail gives the opposite effect and confuses the system, so no broken views.

Glitches & Errors

This is especially common when converting the drawing format (e.g. PDF to DXF). Check the converted one for scrambled lines, random dots etc. If it keeps occurring, some Googling may lead you towards solving the problem

No Title Block

Title block is another confusing element for the computer. Only include lines that are used for cutting.

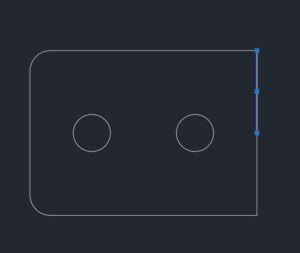

Everything Must Be Connected

If you draw in a 2D environment, like AutoCAD, connect/ join all the lines on the drawing. One way for an easy check is to try to hatch an area – if it is not properly connected, the hatch cannot be done. Just don’t forget to delete the hatched area after a successful try!

If your job fails to automatically price

You will receive an error report, stating what the issue maybe, if there is a faulty drawing, quote price bellow limit. We will receive an alert f there is an issue. If you need help please email directly to info@lasercutting and include your quote reference number and we will manually quote.

Material options

If your chosen material is not on the list please email directly for a quote. For example thicker materials we offer a plasma cutting service up to 30mm

Bending, welding or any secondary services

If in need of secondary services such as bending or welding etc…. Please contact directly for a quote.

Following this advice will give you quick and accurate quotations for your details!